Solar RO using gravity.

Elevation available: Let gravity do the work.

John. F Kennedy said: ”If we could produce fresh water from salt water at a low cost, that would indeed be a great service to humanity, and would dwarf any other scientific accomplishment.” Now, we can do it sustainable.

We developed the world’s first solar powered reverse osmosis without batteries. The best thing: it works 24 hours a day. Our off-grid reverse osmosis technology directly uses solar, wind or wave energy to fill a buffer tank on a hill with seawater. Using the natural force of gravity, the reverse osmosis process receives its required feed: pressurized seawater. We make sure the salt water buffer always contains water for constant fresh water production, resulting in very low cost of water. Then comes the crucial step: the waste energy of the reverse osmosis process is re-used to reduce the required elevation with 80% to 90 m or 290 ft for seawater.

This means unlimited sustainable water from abundant resources for islands and coastal regions. Freshwater scarcity: not anymore.

We use the forces of nature at its best for an independent guilt-free water supply. By avoiding energy conversion losses, batteries & frequent maintenance, savings up to 70% of the water expenses are possible. The bigger, the better, as water generation cost come down with size of production. Sizes of the solar reverse osmosis technology start small and go up to millions of liters of clean water production per day.

Explore how it works by clicking on the components.

Renewable sources as the sun, wind or waves are the only sources of energy used

Either PV panels or wind turbines or wave energy can be utilized, or a combination hereof, depending on the local situation. The footprint is determined by the source water salinity and the daily required fresh water production. The renewable energy sources will be placed at a suitable location of your preference. When renewable energy is available, the energy is directly converted into water displacement by the pump. There is no electricity source required, making the system suitable for off-grid applications.

A salt water source intake will be realized

The source water intake can be realized through a beach well, open ocean intake or borehole. During the design process, we make sure to avoid visual impact and disturbances of the marine environment.

The pump and controller directly utilize the renewable energy available

The salt-water resistant pump displaces the source water towards the elevated water buffer and the reverse osmosis process. Through the combination of the controller and pump, the energy generated by the renewable energy source is very efficiently converted into pumping motion. The pump speed varies depending on the availability of the renewable energy source. It requires no auxiliary energy source and is very low on maintenance.

One pipe installed out of sight connects the components

The pump, elevated water buffer and water treatment plant are connected through one pipeline. Part of the displaced water flows to the elevated water buffer, to cover the periods lacking renewable energy sources. When renewable energy sources are not available, meaning there is no pumping motion, the flow automatically reverses direction by gravity. A constant flow of salt water travels to the water treatment plant. The size of the pipeline depends on the daily required fresh water production. Friction losses are negligible by using smooth pipes, either of HDPE or PVC. This means that it is possible to cover large distances between the pump, elevated water buffer and water treatment plant. The piping can be placed underground to avoid visual impact and will be arranged according to your preference.

The elevated water buffer enables efficient and constant operation

The salt water, which is displaced upwards in periods with sufficient renewable energy sources, is stored inside the elevated water buffer. For periods with limited renewable energy sources, in case of solar panels when thick clouds cover the panels or during the nights, the water buffer will provide the required pressure to drive the water treatment. The elevated buffer can be created as a corrugated galvanized steel tank, including a bladder lining, suitable for coastal environments. An alternative is to create a cistern tank of concrete suitable for salt water storage in any dimension. By customized solutions, it is possible to limit the area required to realize this form of energy storage. Unlike batteries, the water buffer has a long lifetime and does not involve energy conversion losses. The elevation difference required between the water treatment plant and the elevated water buffer is determined by the source water salinity. For seawater with a Total Dissolved Solids (TDS) value of 35.000 ppm, approximately 90 meters ≈ 295 feet is required. For brackish water with a TDS value of 5.000 ppm, approximately 50 meters ≈ 165 feet is required.

Proper pre-filtration results in longer lifetime of the desalination plant

To remove large particles, cartridge filtration will be used. Additional pre-filtration might be required, depending on the source water quality and the source water intake. Optimal pre-filtration design will maximize the lifetime of the reverse osmosis membranes and ensure proper fresh water production.

High quality fresh water is the result of the reverse osmosis process

The Reverse Osmosis (RO) process removes all salts, contaminants, viruses, bacteria, cysts etc. down to a size of 0.0001 micron without requiring chemical treatment. The reverse osmosis filtration technology is based on a multi-layer membrane which filters the water under high water pressure. The technology is suitable for seawater and brackish (ground) water and works by applying pressure on the saline water in the semi-permeable membrane. This pressure is delivered by the energy recovery device. The reverse osmosis process has two exit flows: one containing the fresh water and the other containing the slightly salter water. This concentrated flow is still under 97% of the working pressure. The pressure of the concentrated flow is re-used by the energy recovery device to reduce the required amount of elevation significantly. Because of the elevated water buffer the reverse osmosis process will constantly produce freshwater. This constant operation expands the membrane lifetime considerably.

Post-treatment will be included depending on the intended water use

The fresh water flows towards the fresh water storage tank. In between it can be post-treated when required. The water can be re-mineralized to increase the water quality and the water can be made suitable for lengthy periods of storage.

Energy recovery reuses the excess energy and reduces the required elevation

The pressure of the concentrated flow of water is used to increase the pressure of the incoming flow of salt water going towards the reverse osmosis process. By combining the pressure of the elevated water tank and of the concentrate flow, sufficient pressure will be delivered to purify the saline water. The combination of the energy recovery device and reverse osmosis process ensures a constant production of fresh water. The energy recovery device does not require any auxiliary energy and is a pure mechanical device.

The fresh water will be stored and connected to the distribution system

The produced fresh water is ready to be used directly. As water demand usually fluctuates, the water can be delivered into a fresh water storage which is connected to the distribution system. The fresh water can also be transported over large distances to reach the end-user. Depending on the intended use of the water, we can make sure it will meet all quality requirements.

Desalination without a carbon footprint.

The solutions can be designed for any requested water production. We provide containerized units for plug and play installation, or integrate separate components to your preference into the (existing) infrastructure.

| Footprint indication | 10 m³/day 2,640 gallon/day |

100 m³/day 26,400 gallon/day |

1.000 m³/day 264,000 gallon/day |

|---|---|---|---|

| Solar panels m² (ft²) | 64 m² (690 ft²) | 640 m² (6,900 ft²) | 6.400 m² (69,000 ft²) |

| Desalination unit m² (ft²) | 7 m² (75 ft²) | 25 m² (270 ft²) | 150 m² (1,615 ft²) |

| Elevated buffer m3 (US gallon) | 100 m3 (26,410 gal) | 1.000 m3 (264,100 gal) | 10.000 m3 (2,641,000 gal) |

| Buffer diameter m (ft), h = 3 m | 6,5 m (21 ft) | 20,6 m (68 ft) | 65,1 m (214 ft) |

A video on how to solve fresh water scarcity,

using only the sea, sun, earth & wind:

Gravity reference: British Virgin Islands.

Private retreat enjoying solar-powered desalination using gravity.

“My family and I selected Elemental Water Makers to provide fresh water for our home in the British Virgin Islands because they presented us with a cost-effective solution to creating a continuous supply of very high-quality water, without monthly electrical bills and without using fossil fuels. Their technical people listened carefully to our needs, were a pleasure to work with, and in the end, designed a custom solution that works as promised.

After struggling for years with high electric costs, power outages and the unreliable water quality and volumes produced by our home’s traditional reverse osmosis system, we now enjoy more than 3,300 gallons of fresh water every day, using nothing more than sunshine and the natural elevation of our property. And in the process, my children and I are helping to reduce the Virgin Islands’ carbon footprint and preserve its precious environment for future generations.

We would recommend Elemental Water Makers without hesitation.”

Time-tested components.

Financial case: solar RO by gravity.

A resort cutting water expenses using solar desalination.

The problem: expensive utility water

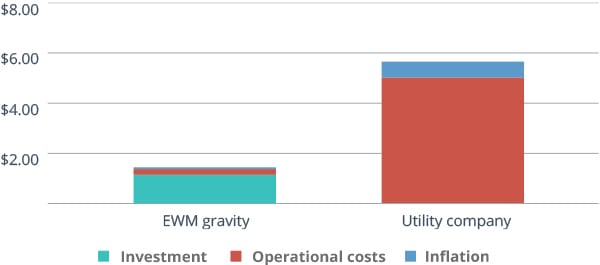

The resort receives its piped water from the island public utility company and faces a commercial rate of 5 $/m³. With a consumption of 50 m³/day, the water expenses weigh heavily on the resort’s operational expenses. Some days, there is no water available and some days, the quality doesn’t meet the high resort’s standards.

The solution: solar desalination using gravity

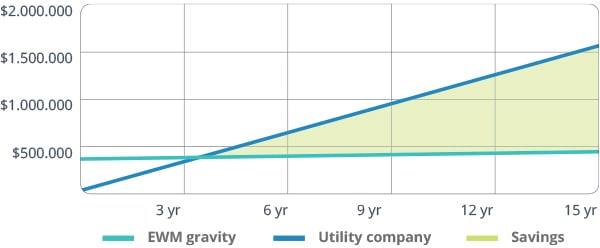

Enter Elemental Water Makers. Through investing in the solar reverse osmosis gravity-assisted solution, 70% savings on the water expenses are enjoyed, resulting in over 1.100.000 $. The solution’s payback is within 4 years.

The benefits: reliable savings and guilt-free water

Besides these financial savings, the resort has become independent on the availability and price of energy, provide high-quality water to their guest, save 100 ton CO2 per year, enjoys stress-free operation & remote monitoring and offer their clients a sustainable experience.

Assumptions: costs including installation and training | Yearly inflation of 2% | Local water price is 5 $/m³ | Water intake available | Financial lifetime 15 yrs | Technical lifetime >20 yrs | OpEx include consumables, spare parts and membrane replacement.

Water expenses

Water tariff in $/m3

Over $1,000,000 in total savings.